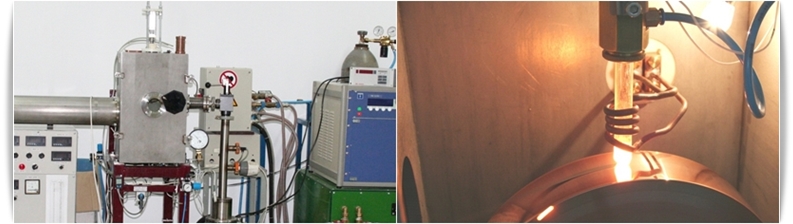

The technique for the preparation of the amorphous and nanocrystalline metal ribbons consists in introducing a piece of master alloy in a quartz crucible, melting the alloy by an electromagnetic field produced by an induction coil and ejecting the molten metal onto a rotating copper wheel. The quartz crucible is provided at the bottom with an orifice (circular or rectangular) and is positioned vertically, inside the induction coil, above the copper disc. The copper disc rotates at different speeds.

Melt-spun ribbons equipment

The quartz tube - copper disc- induction coil assembly can be located in a vacuum chamber (p~2x10-4 mbar). The molten metal is ejected, under the action of inert gas pressure (Argon - Ar), on the outer surface of the copper wheel which is rotating at a tangential speed of the order of tens of meters per second. By the ultra-rapid cooling of the melt at rates of between 104-106 K/s, the jet solidifies on the cooper disc forming the amorphous ribbons.

Technical specifications:

- Vacuum: p~2x10-4 mbar

- Circular or rectangular nozzle of the quartz crucible

- Tangential speed of disc: 1 - 35 m/s

- Argon pressure: 0.15 - 0.25 mbar.

Services:

- Design, development, and technology transfer of melt spun equipment

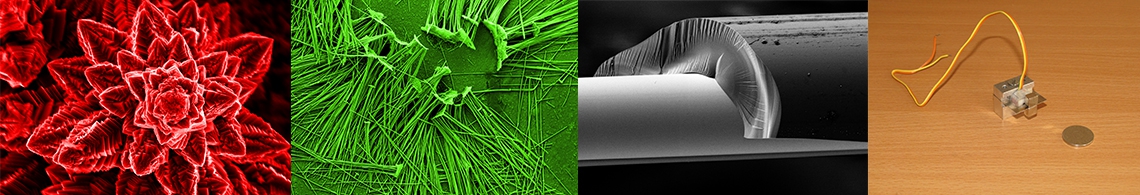

- Preparation of a wide range of amorphous and nanocrystalline metal ribbons by rapid quenching from the melt.