The ARC DISCHARGE EQUIPMENT is used for the preparation of amorphous and crystalline nanoparticles with dimensions up to hundreds of nanometres, depending on the preparation conditions. Arc discharge equipment consists mainly of an enclosure/reaction chamber where vacuum can be made, a cooling system, two electrodes (a wolfram, W, electrode and a W crucible - cooled with water), a vacuum system, and an electrical source. The vacuum chamber has a cylindrical shape and the lateral wall that is cooled is designed to collect nanopowders. The electric arc is ignited between the W electrode and the W crucible (where the source material is placed), using a high frequency initiator. By heating, the metal atoms are released from the metal surface and evaporate. When the metal vapour was supersaturated, a new phase was nucleated. The droplets were rapidly cooled and combined to form primary particles. The free inert gas convection developing between the hot evaporation source and the cooled collection cylinder is transporting the particles out of this nucleation and growth region to the inner walls of the cylinder. The nanopowders could be collected from different areas of the enclosure.

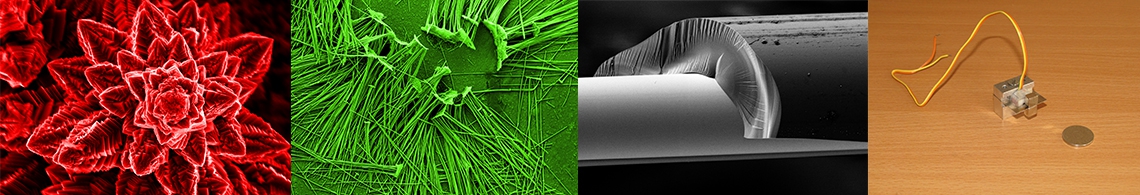

Arc discharge equipment

Technical specifications:

- Temperature enclosure of 0ºC to -17ºC

- Base pressure: 2x10-4 mbar

- Relative working pressure: - 0.85 to - 0.5 bar, with respect to atmospheric pressure

- Working gas: He (purity 99.999%)

- Discharge current: 40 ÷ 200 A

- Time discharge: from 2 to 15 minutes (depending on material).

Services: Preparation of metallic amorphous and nanocrystalline micro-and nanopowders.