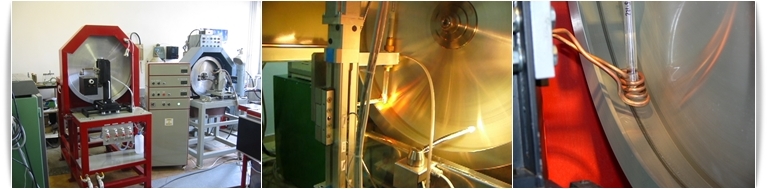

The in rotating water quenching technique used for amorphous and nanocrystalline conventional wires preparation consists of melting the metal alloy in a quartz tube using a high-frequency inductor and ejecting of the molten alloy using an argon overpressure, in a rotating water layer. The main parameters are computer controlled.

In rotating water quenched wires equipment

The diameter of the wires depends mainly on the dimensions of the ejection nozzle. In order to obtain a wire with uniform geometry, the control of value of the ratio between the melt flow velocity and the peripheral speed of the rotating water layer is essential.

Technical specifications:

- Rotating speed of disk: 150 - 400 rpm

- Generator power: 0 - 5 kW

- Argon pressure: 1- 8 bar.

Services:

- Design, development, and technology transfer of equipment for amorphous and nanocrystalline conventional wires preparation by “in rotating water quenching”

- Preparation of a wide range of amorphous and nanocrystalline conventional wires with diameters ranging between 80 and 150 micrometres and lengths up to 100 metres.