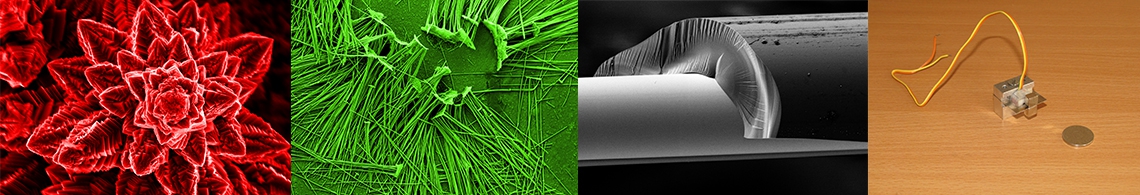

FOCUSED ION BEAM (NEON 40 EsB / Carl Zeiss GmbH)

FOCUSED ION BEAM (FIB) is a high-tech facility used in the micro-and nanotechnologies domain. The NEON 40 EsB combines imaging and analytical performance of a Scanning Electron Microscope (SEM) with the processing ability of a FIB. FIB system can be used for ionic etching of samples for different applications: cross-sections in single layer and multilayer films for complex morphological and compositional studies by Transmission Electron Microscopy (TEM); nano-processing of planar surfaces for nanostructures; nano-processing of bulk materials for micro- and nano-products; etc. The ion beam can be used additionally for the deposition of metals or insulators. FIB is also used to perform complex nanoindentation activities in ceramic, metallic or polymeric membranes with micrometric thickness for the subsequent development of nanopillars and / or nanowire networks, and planar structures.

This equipment comprises EDS and EBSD, SE, BSE detectors, In-Lens, manipulators for TEM sample preparation, plasma cleaning system, module for ion beam nanolithography, and Gas Injection System (GIS) deposition system. The NEON 40 EsB system operates with two beams, one electron beam and one ion beam. Both beams can be used independently. The FIB system contains an ion source (gallium), a set of electrostatic lenses and a surface scanning system with nanometric precision, module of ultrahigh- resolution nanolithography (nanopatternig engine) with ion beam, high - resolution Scanning Electron Microscopy column (UHR-SEM). The SEM is designed for microscopic examinations of the samples.

FIB (Neon 40 EsB/Carl Zeiss GmbH)

Technical specifications:

- Acceleration voltage: 0.1 - 30 kV (electron optics); 2 - 30 kV (FIB)

- Resolution - electron optics: 1.1 ÷ 2.5 nm at U = 20 kV ÷ 1 kV

- Resolution - FIB: 7 nm at U = 30 kV

- Probe current: 4 pA - 30 nA (electron optics)

1 pA - 50 nA (FIB) - Magnification: 12× - 900 k× (electron optics)

600× - 500 k× (FIB).Services: Preparation of TEM samples; Morphological images; Compositional analysis by EDX; Nano-processing (milling and polishing) of surfaces for nanostructures and bulk materials for micro-and nanoproducts.