The atomisation process consists in the fragmentation of a molten alloy jet in droplets and their rapid cooling with 2 jets of fluids (gas and water). The two fluid jets are directed to the molten alloy jet by means of two nozzles.

The GAS-LIQUID ATOMISATION EQUIPMENT consists of a quartz tube in which the solid material is placed, the induction coil for melting the material, and two nozzles for the atomization fluids (gas and water). The molten metal is pushed under the action of an inert gas (i.e. Argon - Ar), is ejected through the circular orifice from the end of the quartz tube, as a jet of melt, and it is broken down into particles by the simultaneous action of the gas and liquid jets.The gas and water nozzles are fixed to a support by means of two springs, this facilitating the modification of the angles of the fluid jets with respect to the molten alloy jet, with effect on the structure of particles and their size (National patent).

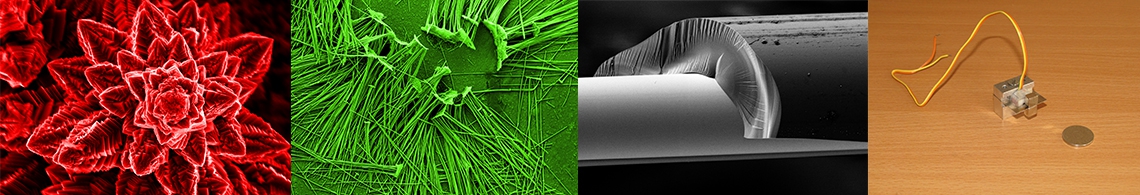

Equipment for amorphous powders preparation by gas-liquid atomization

Technical specifications:

- Angle between the nozzle axes and the support on which they are attached: 25°÷ 50°

- Cooling fluids: Ar - water

- Particles size: 50 ÷ 200 µm.

Services:

- Design, development, and technology transfer of equipment for amorphous powders preparation by gas-liquid atomization

- Preparation of amorphous micro- and nanopowders.