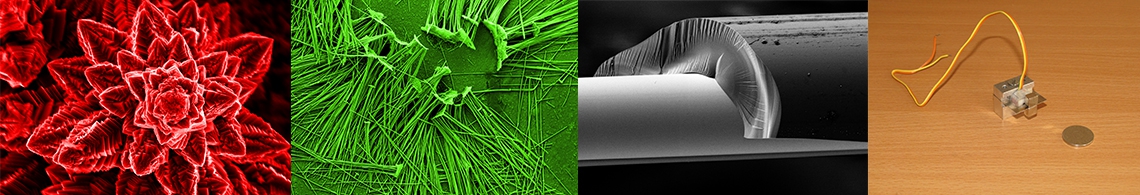

GATAN DIMPLE GRINDER - Model 656 is an instrument used to produce circular dimples (spherical or flat-bottomed profile) in materials such as ceramics, semiconductors, metals, and combinations thereof. This equipment is used mainly to prepare samples for TEM (Transmission Electron Microscope) and Auger spectroscope.

GATAN DIMPLE GRINDER - Model 656 offers a fast and reliable mechanical method of pre-thinning to near electron transparency greatly reducing ion milling times and uneven thinning. DIMPLE GRIDER reduces the central region of a typical 100 µm thick, 3 mm diameter specimen blank to a few microns in times ranging from 20 minutes for silicon to 100 minutes for sapphire. For particularly fragile specimens a small 10 mm diameter grinding wheel leaves a wider rim than the standard 15 mm diameter wheels and provides even better specimen support.

Moreover, a large 20 mm diameter grinding wheel is available for making shallow dimples and exposing near surface concentration gradients, for Auger spectroscopy.

The GATAN DIMPLE GRINDER is also equipped with a dual measuring system (i.e. a digital, electronic micro-meter sets-end-stop and an analogic dial indicator) which gives continuous display of the dimple depth.

Gatan Dimple Grinder - Model 656

Technical specifications:

- Size: 300mmW x 200mmD x 125mmH

- Power requirements: Universal voltage 100 VAC - 240 VAC, 50/60 Hz

- Controls: Table rotation (l / 0); grinding wheel rotation (l / 0); transmitted light (l / 0); grinding wheel speed (variable); Auto-Terminator (l / 0); Micro-meter zero; Grinding wheel load (0-40 gms).

Services: Pre-thinning of materials for preparation of the samples for TEM, optical, and Auger spectroscopy analysis.