Lapping is an abrasive polishing procedure made with abrasive powders (silicon carbide, boron carbide, diamond) suspended in a liquid (water, oil, petroleum or oil - petroleum mixture) applied between the work-piece and the tool (i.e. discs made of cast iron, copper or soft steel). This procedure is achieved by pressing the work-piece with a pressure, p, and by circular displacements between the tool and the work-piece.

Model 15 Open Face LAPPING MACHINE is used where work-pieces/samples are either large in size and can be lapped under their own weight or where pressure application by hand weights is sufficient. Using this equipment, worn component parts as valve bodies, discs, gears, vanes, valve plates, and shaft seals are reconditioned and salvaged, benefiting from the lapping process.

Model 15 Open Face Lapping Machine

Technical features:

- Heavy duty cast aluminium base

- Wrap-around worktable facilitates parts handling

- Three conditioning rings with roller yoke and bearing assemblies to facilitate in-process plate flatness control

- Abrasive feed system designed for water or oil based lapping slurries, consisting of a 1/25hp/0.03 kW pump, tank and three outlet system with individual variable flow control. This permits uniform lapping rates at each work station

- High torque drive unit with 1/2hp/0.25 kW motor and gear reducer

- Electrical system: 110 volts; 60 Hz; 1 phase

- Automatic digital cycle timer: time ranges from 0.1 to 999 seconds, minutes or hours

- Roughness: Ra = 0.012,...., 0.1 µm

- Deviations from parallelism: up to ± 1 mm.

Services:

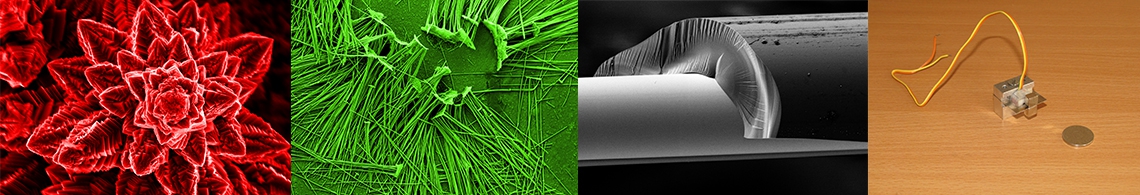

- Surface polishing of different materials used for topological and morphological analysis by optical microscopy and Scanning Electron Microscopy (SEM)

- Polishing of different component parts of the devices as sensors, actuators, etc.