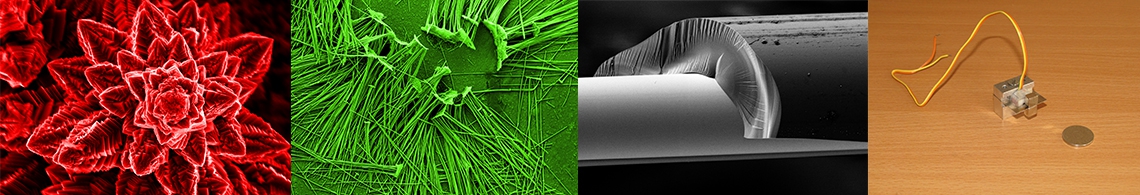

RETSCH PLANETARY BALL MILL PM 200 and Sieving Device AS 200

Planetary Ball Mills are used to grind and mix materials that are soft, medium hard to extremely hard, brittle or fibrous. The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and consequently short grinding times. In the case of RETSCH PLANETARY BALL MILL PM 200, the grinding jars are arranged eccentrically on the sun wheel of the planetary ball mill. The grinding balls in the grinding jars are subjected to superimposed rotational movements, the so-called Coriolis forces. The difference in speeds between the balls and grinding jars produces an interaction between frictional and impact forces, which releases high dynamic energies. The interplay between these forces produces the high degree of size reduction of the planetary ball mill. This planetary mill is equipped with RETSCH sieve shakers which can carry out both wet and dry particle size analyses in a particle size range between 20 µm and 500 µm.

Retsch planetary ball mill PM 200 and sieving device AS 200

Technical specifications:

- Powerful and quick grinding down to nano range

- Reproducible results due to energy and speed control

- Maximum feed grain size: up to < 4 mm, but dependent on the material

- Maximum feed volume: up to 2x125 ml, depending on the grinding bowl volume

- Final fineness: < 1 µm, for colloidal grinding < 0.1 µm

- 2 different grinding modes (dry and wet)

- Wide range of materials for contamination free grinding.

Services: Preparation of micro-and nanopowders; dimensional sorting.