Project full title:

MAGNETIC NANOCOMPOSITE MATERIALS BASED ON Ce2(FeCo)14B/αFe, FOR PERMANENT MAGNET WITHOUT CRITICAL RARE EARTHS

(MATERIALE MAGNETICE NANOCOMPOZITE DE TIP Ce2(FeCo)14B/αFe PENTRU MAGNEȚI PERMANENȚI FĂRĂ PĂMÂNTURI RARE CRITICE)

Project Acronym:

MAGRISK

Project code: PN-II-RU-TE-2014-4-1431

Funding Agency:

Executive Agency for Higher Education, Research, Development and Innovation Funding (UEFISCDI)

Project Duration: 1/10/2015-30/09/2017 (24 months)

Project Coordinator:

Dr. Marian GRIGORAŞ

Institutul Național de Cercetare-Dezvoltare pentru Fizică Tehnică – IFT Iași

Bulevardul D. Mangeron nr. 47, 700050 Iași, România

E-mail: mgrigoras@phys-iasi.ro

Tel: +40 232 430680

Fax: +40 232 231132

Project Funding:

122,727.00 EUR (540,000.00 RON)

Project Summary

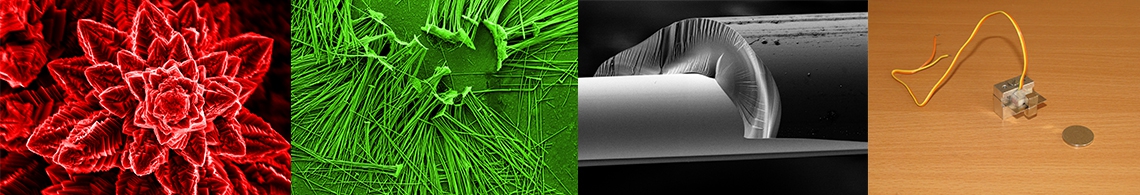

The strongest and most used permanent magnets available today are based on Nd-Fe-B, with additions of Dy, Pr, Tb etc. However, Nd, Dy and Pr are considered as critical rare earths elements. Consequently, there is a strong need to find and produce new permanent magnets due to: (i) the exponential growth of technological application areas (especially the energy "green" ones); (ii) the overall resources limitations; (iii) the explosion of critical rare earth materials price (strategic materials) and export restrictions imposed by China (the main supplier) on rare earths. The project proposes to replace Nd with cerium (Ce) and to study the physical properties of Ce2(FeCo)14B/αFe amorphous/nanocrystalline materials, with applications for high performance nanocomposite permanent magnets. The motivation for this choice lies in the fact that Ce is found in abundance, being present 4 times more than Nd and Pr together. However, the total replacement of Nd with Ce decreases the Curie temperature (Tc), saturation magnetization and, implicitly, the energy product (BH)max. The proposed project comes with a number of solutions in order to increase: (1) the Tc by partial substitution of Fe with Co, (2) (BH)max by nitrogenation (interstitial introduction of the nitrogen in the structure of Ce2(FeCo)14B) and (3) by favoring a high exchange coupling between the magnetic phases of Ce2(FeCo)14B/αFe-type nanocomposite permanent magnets.

Main Objective of the Project

To develop a new generation of magnetic materials for permanent magnets, which is a more urgent than ever goal, given the demand for green energy and more efficient engines.

Specific Objectives of the Project

- Preparation of ribbons with optimized composition and establishing the parameters of annealing (time, temperature) and/or magnetic treatment in order to control the hard magnetic phase formation.

- Milling of CeFeB-based melts-spun ribbons in a controlled atmosphere, mixing the micropowders and determining the optimal ratio of hard phase (based on Ce-Fe-B)/soft phase (αFe and/or FeCe) for obtaining composite powders.

- Identification and optimization of compaction factors/alignment (time, pressure, temperature, magnetic field) with effect on the magnetic characteristics of Ce2(FeCo)14B/αFe nanocomposite materials compacted by Spark Plasma Sintering method (SPS).

- Increase of the Curie temperature and operating temperature > 2000C for the new type of permanent magnets through elements substitution and nitrogenation; thermal stability study.

- Dissemination of the results.

Objectives related to the specificity of the project type:

- Training / specialization of young researchers in a field of top scientific research and the increase of the international visibility of the young researchers.

- Developing the skills of young researchers to lead research teams and manage research projects.

- Consolidation of the critical mass of young researchers from INCDFT-IFT Iasi for participation in interdisciplinary projects and obtaining international performance.

Estimated results:

- Preparation of Ce-Fe-B-based melt-spun ribbons with nanocrystalline structure and optimized composition.

- Preparation of Ce2(FeCo)14B/αFe-type nanostructured micropowders.

- Obtain Ce2(FeCo)14B/αFe nanocomposite permanent magnets in disk shapes by Spark Plasma Sintering, with energy products (BH)max over 20 MGOe.

- Articles published in ISI journals.