EQUIPMENT FOR THE PREPARATION OF AMORPHOUS AND NANOCRYSTALLINE/NANOSTRUCTURED MATERIALS by rapid quenching from the melt:

RAPID QUENCHING FROM THE MELT is a process used for producing amorphous metal and metallic glassy alloys. In the rapid quenching from the melt process, a molten metal alloy system is subjected to very rapid cooling rate ranging between 104 and 106 K/s.

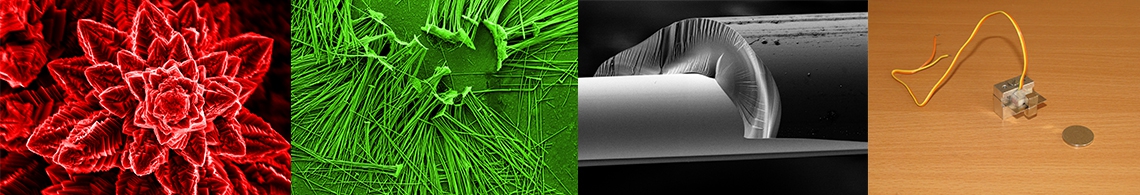

Amorphous and nanocrystaline/nanostructured materials, under different geometrical shapes, are prepared at NIRDTP by rapid quenching from the melt, using the following methods:

- melt-spinning method for thin and thick ribbons

- in-rotating-water melt spinning method for conventional wires

- glass-coated melt spinning method for glass-coated micro-nanowires

- injection method for amorphous and nanocrystalline bulk materials with millimetres dimensions (rods, toroids, tubes, discs, etc.).

NIRDTP Iasi has the research infrastructure (a range of in house build equipment) for the preparation of amorphous and nanocrystalline /nanostructured materials:

- Equipment for ribbons preparation by rapid cooling of the melt on a rotating metal disc, in vacuum and controlled atmosphere

- Equipment for wires preparation by rapid melt cooling in rotating water layer

- Equipment for glass - coated micro and nanowires preparation (International Patents EP, US, CA)

- Equipment for 3-D shaped (bulk) materials preparation by rapid solidification, in vacuum and in controlled atmosphere

Some of these equipment are unique in Romania and even in Europe.

The complex equipment for the preparation of amorphous and nanocrystalline materials include: laser drilling system for the preparation of nozzles in the quartz crucibles, special chambers for materials processing in air, vacuum and inert atmosphere, induction coil-crucible systems, medium and high frequency generators, and special equipment for the process parameters control.